Weld porosity can be compared to the cavity in the mouth. If you do not keep things clean, then it may leave spots which will weaken the weld. Thus, it can fall out anytime. Weld porosity occurs when gas or contaminant is absorbed into the weld puddle.

The impure welds are known as cavities. Porosity can cause the project to be weak and eventually collapse. You can save yourself the trouble by preventing porosity from taking place. Here are tips that will be useful when it comes to porosity in welding.

Keep it clean

You have to make sure that the surface of your material is clean and dry. However, with welding not much is clean. If the surface is not clean, then it could result in rust, oil and grease formation. Such can mix with the weld puddle and trap gas which can cause bubbles when material cools down.

You have to make sure that the surface of your material is clean and dry. However, with welding not much is clean. If the surface is not clean, then it could result in rust, oil and grease formation. Such can mix with the weld puddle and trap gas which can cause bubbles when material cools down.

You should also watch out for chemical reactions that can result in porosity. Gas can be trapped in the butt joints and T-joints. Aluminum is tricky, and you need to clean it before you get started.

Check the gas flow

You should also monitor the flow coming from your gas shield. If the flow is powerful, then the air will be disturbed. It can result in weld puddle mixing with the contaminants. In as much as the flow rates differ, you have to make sure that you choose the correct flow.

Selecting the proper flow will improve efficiency and ensure that you get quality yield. You can seek advice if you are not sure which the correct flow rate is.

Check equipment

The hoses are subject to wear and tear with time. You need to check all the connections to make sure that you have an accurate flow. It is advisable to check the tip of your weld gun to ensure that it is clean.

The tip can become clogged and lead to impurities in your weld. You should also check the tension for any wire spool hub. Having a poor tension means that your wore feeding will have poor performance

Workspace condition

At times welding shops get very hot, and you have to think twice before you open the door. You should monitor your workplace to ensure that there are currents that can affect the gash shield.

At times welding shops get very hot, and you have to think twice before you open the door. You should monitor your workplace to ensure that there are currents that can affect the gash shield.

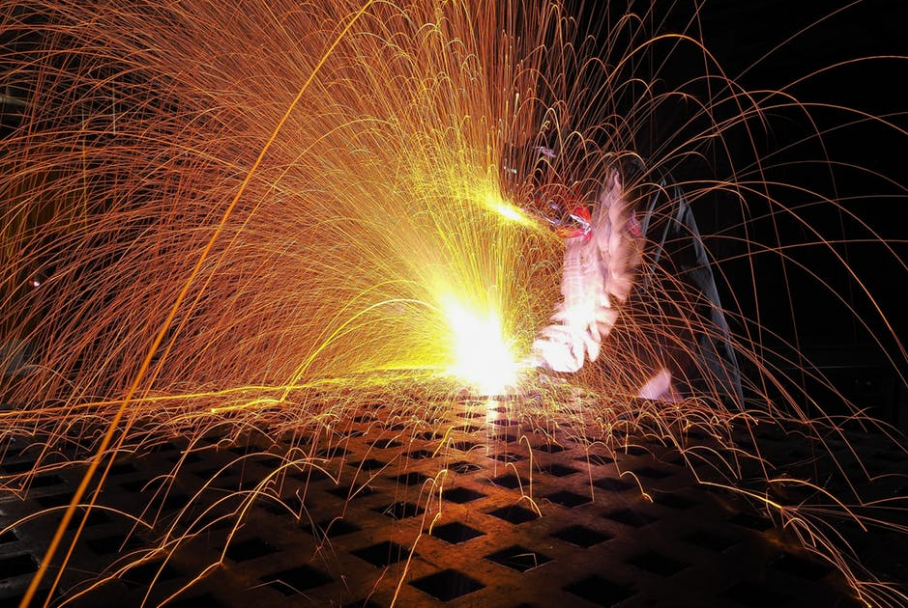

The gun should be as far away as possible from the weld site. In doing so, you will prevent the air from seeping into the weld puddle. The video below highlights how to stop weld porosity.